Step 1 Track your process information Your effectiveness is affected by these 6 most common…

admin23 January 2020

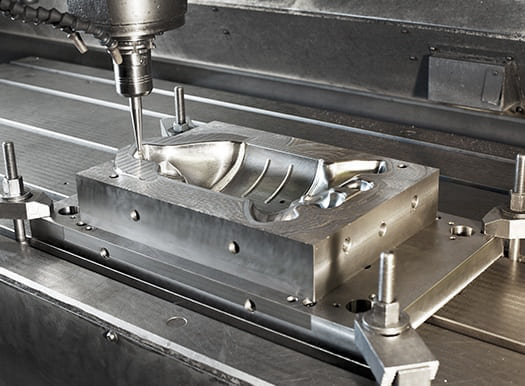

There are 11+2 molding parameters that make a difference in the quality of the part.…

admin22 January 2020

This video shows how packing pressure influences the dimensions of the mold. Plastic melt has…

admin14 January 2020