Maes Insights helps you get to your finished product smoothly. With years of experience in injection molding. From a 100+ well known companies Maes Insights delivers the perfect match in product designers, material suppliers, mold manufacturers and production facilities specifically for your product.

From idea to finished product

Supervising your injection molding process

Research

Feasibility Check & Material research

Development

Design, prototype & CAD modeling

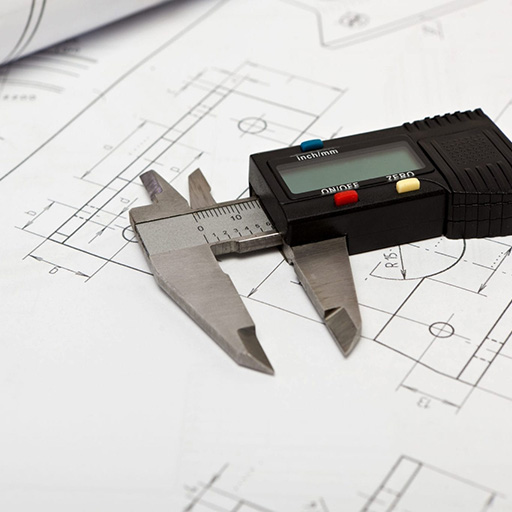

Verification & Validation

Testing & Measure

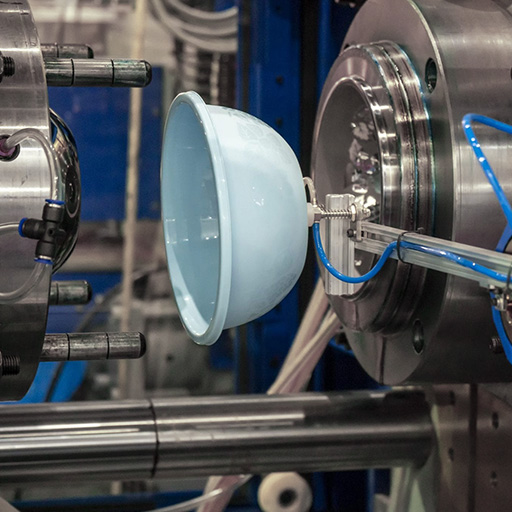

Realization

Molds & Tools

Production

1K, 2K & Cleanroom

Assembly

Additional services, product quality & finish

Would you like to optimize your injection molding process and save 30% or more?

Leave your details so that we can give you more information or schedule an appointment.

- Broad industry knowledge

- Large relationship network

- Your injection mold broker

- High support level

- High quality education level